Precision in Every Cut: Premier Concrete Cutting & Drilling Services in Ohio

OCSD’s Commitment to Precision and Innovation

Established on a foundation of unwavering commitment to quality, our team brings over four decades of expertise to every project, large or small. Our services are not just about making precise cuts or perfect holes; they're about shaping the future of construction with each concrete slab or structure we touch.

At Ohio Concrete Saw and Drilling, we understand the evolving needs of modern construction. Whether it's intricate coring for complex installations or precision sawing for alterations, our skilled operators employ the latest technology to ensure unparalleled accuracy. Our dedication to staying ahead of industry trends is matched only by our commitment to safety and efficiency, ensuring every job is completed to the highest standards.

We believe in building lasting relationships with our clients, grounded in trust and enhanced by our proven track record. Our flexibility in scheduling, including availability for weekend and night work, ensures that we align with the unique timelines of our clients' projects. It's not just about meeting expectations; it's about exceeding them with every cut and drill.

Ohio Concrete is more than a service provider; we are partners in progress, dedicated to elevating the standards of concrete cutting and drilling across Ohio and beyond. When you choose OCSD, you're not just choosing a contractor; you're choosing a legacy of excellence and a future of innovation.

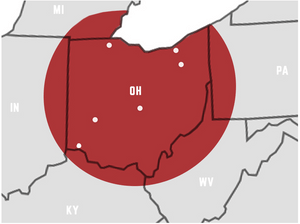

We service all of Ohio, with offices in Toledo, Dayton, Cleveland / Akron and Columbus. We also serve the surrounding areas of Michigan, Pennsylvania, Indiana, Kentucky and West Virginia.

Concrete Services We Provide

Concrete Cutting & Sawing Services

Mastering a range of concrete cutting and sawing services, we excel in asphalt and flat/slab sawing, precise wall & wire sawing, and horizontal curb cutting.

Utilizing advanced equipment, our team ensures accurate and efficient execution for every project.

Our services are designed to meet diverse construction needs with an emphasis on precision and excellence.

Concrete Coring & Drilling Services

Specializing in diverse concrete coring and drilling services, we cater to a variety of project requirements. Our expertise encompasses concrete and asphalt coring, vertical and horizontal core drilling, specialized services like manhole coring and drilling, pipe boots installation, and anchor drilling.

Each service is carried out with the utmost precision, utilizing state-of-the-art technology to ensure optimal results tailored to the specific demands of each project.

Specialty Installation Services

Our specialty installation services are designed to cater to unique construction needs, ranging from the cutting of egress windows and doors to the precise setting of bumper and bollard posts. We also excel in anchor installation and safety grooving, ensuring every project meets the highest standards of safety and functionality. Additionally, our advanced demolition robot technology streamlines complex demolition tasks, offering efficient and safe, controlled demolition solutions.

Concrete Treatment & Correction Services

Book reliable concrete treatment and correction services. Our capabilities extend to floor grinding and shaving, thorough surface preparation, high-quality polishing, burnishing and sealing. We are also proficient in joint repair, slab stabilization, providing precise scraping/shaving and efficient milling solutions.

Each service is tailored to restore and enhance concrete structures, ensuring durability and aesthetic appeal.

Related Services

We offer a comprehensive support for various construction phases, encompassing mini electric excavation for precise site preparation and effective concrete removal. We specialize in concrete demolition, employing advanced techniques for efficient and controlled dismantling. Our ground penetrating radar service offers crucial insights for underground utility mapping, enhancing project safety and planning. Additionally, our demolition services are tailored to meet the specific needs of each project, ensuring thorough and safe structural removal.

Ohio's Premier Concrete Cutting Contractor

Ohio Concrete Sawing and Drilling is the premier concrete cutting contractor in Ohio, and next year we celebrate 40 years of continuous service! We are proud of the milestone but look to the future to continue our success of serving our customers. Concrete Cutting is not the most glamorous construction trade but we are proud of the work we do and how we do it.

Continual Advancement in Equipment and Technology at Ohio Concrete

At Ohio Concrete Sawing & Drilling, we are steadfast in our commitment to technological innovation and equipment modernization. Our aim is to streamline your project with the most advanced and efficient solutions. Here's how we maintain our edge in the concrete industry:

Latest Technology Integration: We are dedicated to integrating state-of-the-art technology like Building Information Modeling (BIM). This advanced 3D design and modeling software enhances our planning, design, and management capabilities, fostering a collaborative environment for architects, engineers, and contractors. This integration is crucial for reducing waste and avoiding delays, ensuring a smoother project lifecycle.

Intelligent Equipment Utilization: Embracing the trend of intelligent equipment, we've equipped our fleet with IoT sensors and GPS trackers. This technology not only optimizes the production cycle but also enables predictive maintenance. It ensures real-time updates and quick responsiveness to any on-site changes, significantly enhancing project management and execution.

High-Performance Diamond Tooling: In our quest for excellence, we've adopted Ultra-High Performance Diamond Tool technology. UHPD's enhanced productivity and speed for the cutting process reducing cost and increasing safety. This innovation underscores our commitment to delivering cutting edge robust concrete solutions.

Continuous Equipment Updates: We regularly upgrade our machinery, including High Cycle wall saws and wire saws, to tackle the most challenging cutting services efficiently. Our fleet is also equipped with the latest coring machines and flat saws, ensuring the most ergonomic and efficient technology is at our disposal, further emphasizing our dedication to innovation and excellence in the concrete sawing and drilling industry.

Our Team is Growing with New Talent and Skill

Just like with any business today, we are adding new team members to our staff in an effort to ensure that we are meeting the demands of the customers while insuring our company in the future. The training of new employees starts with general site awareness and an introduction to the tools. As they work with our senior operators, they revisit the training to ensure comfort. After their shadowing period, a newer operator is given the simplest jobs to build confidence and test their retention. As with all employees in all fields, some grasp the techniques quicker than others. We continue our work specific training. In case you were wondering, we are compliant with OSHA Silica training and standards.

We've Kept the Same High Values and Quality Work Ethic Since Day One

So, as we improve the technology and add new blood, it is important to hold to the values that allowed us to serve the concrete cutting industry for 40 years. Those values include safety, responsiveness, and high quality results. You can continue to rely on our concrete coring and cutting expertise just as you always have as we invest in the future. Please continue to call us for all of your cutting, drilling and coring needs in asphalt, concrete, and block. If you are new customer, give us an opportunity to earn your business and call today for a free estimate.

Why Partner with Ohio Concrete Sawing & Drilling

OCSD stands out as a premier provider of concrete and asphalt services, extending its expertise across Ohio and neighboring regions. Here’s why:

Extensive Experience and Growth: Founded in 1981, Ohio Concrete has expanded its reach across Ohio and neighboring states, continuously growing and adapting to meet the needs of a dynamic industry and next-generation technology.

Adaptation and Innovation: The company has evolved over the last 15 years, adopting environmentally friendly practices, expanding services, and creating industry-specific safety training programs. This proactive approach ensures modern, efficient solutions to concrete challenges.

Customer-Centric Approach: Our company prioritizes long-term customer relationships, ensuring timely service, quality equipment, and well-trained personnel. Their commitment to fair pricing and fulfilling work as per client expectations is a cornerstone of their business.

Commitment to Safety: Safety is paramount, with rigorous training for employees to recognize and handle potential hazards. This commitment extends to ensuring the safety of both their team and clients.

Capability to Handle Diverse Projects: As one of the Midwest's largest concrete cutting companies, Ohio Concrete has the capacity and resources to manage both large and small projects efficiently.

Investment in Top-Tier Equipment: OCSD invests in advanced equipment and technology, ensuring projects are completed on time and within budget. This includes trucks, trailers, and specialized tools for concrete drilling and cutting.

Skilled Workforce: Employing the best talent in the industry, the company ensures that skilled operators are available across various locations to provide quick and effective service.

Comprehensive Service Range: Offering a wide array of services including concrete cutting, sawing, coring, drilling, grinding, polishing, and more, Ohio Concrete is equipped to handle diverse construction and remodeling challenges.

Efficiency at Every Step: With expertise in handling heavy and complex concrete structures, the company has the necessary tools and expertise to execute projects with precision and efficiency.

Quality Assurance: Ohio Concrete's dedication to delivering high-quality work with competitive pricing has built lasting relationships with clients who rely on them as their preferred concrete services contractor.

Project "Plane Ole Cutting"

North American Aerospace Industries is a leading recycler of decommissioned aircrafts. Normally, the components of an aircraft are either recycled or repurposed to fix other planes. But this plane's destiny is an extraordinary one - it will be transformed into a luxurious "glamping" destination.

Wire sawing presents a powerful tool in tricky cutting applications. It can be used to easily slice through concrete, steel, aluminum or any other metal with maximum precision. The wire is impregnated with diamond beads and scraped over a surface to cut a line. Given the immense size of the aircraft, a wire saw was deemed to be the most feasible way to make the necessary cuts.

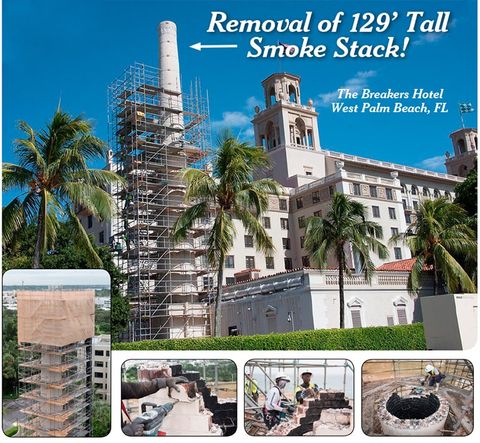

No Job Too Big or Tall

Removal of 129" Tall Smoke Stack

Our sister-company, ABC Concrete Cutting Inc. was contracted by The Weitz Company to remove a smoke stack which was part of the original construction of the Breakers Hotel built in 1929 when the boilers were powered by coal.